Products

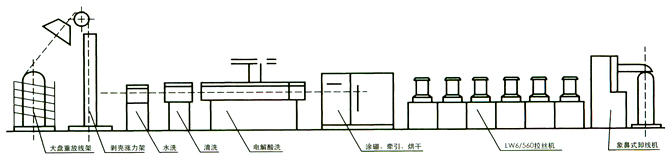

| Protection welding wire flow chart | ||||||||||

The CO2 gas protection welding wire, buries the are to bury the ine whole set production equipment

Rough automatic production line general arrangement Rough production line:Frequency conversion velocity modulation PLC control Highest line speed

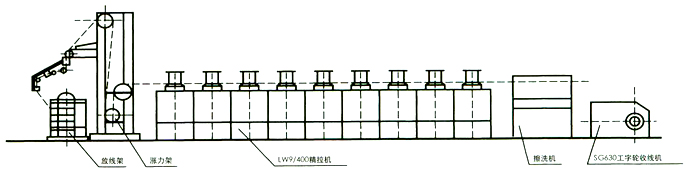

The essence pulls the automatic production line general arrangement Essence pulls production line:Frequency conversion velocity modulation PLC control Higest line speed

The first step:First processes

The second step:Roungh

Widening of the former for wire-line processing,and supporting the use of coarse Rafah. Handling wire:φ4-φ10mm Maximum speed:2.5m/s The third step:The essence pulls

The fourth step:Coppre-Plating

CO2 wire copper production line φ0.6-φ1.6 Copper wire submerged arc welding production lines:φ2-φ64 4Line-25-copper lines,applicable to 2000T-20000T output

The fifth step:The essence circles

| ||||||||||

Next:Straight Line Drawing Machine | ||||||||||

|

简体中文

简体中文 ENGLISH

ENGLISH

苏公安备:32020502000058

苏公安备:32020502000058